Robot 3D bridge printing in China

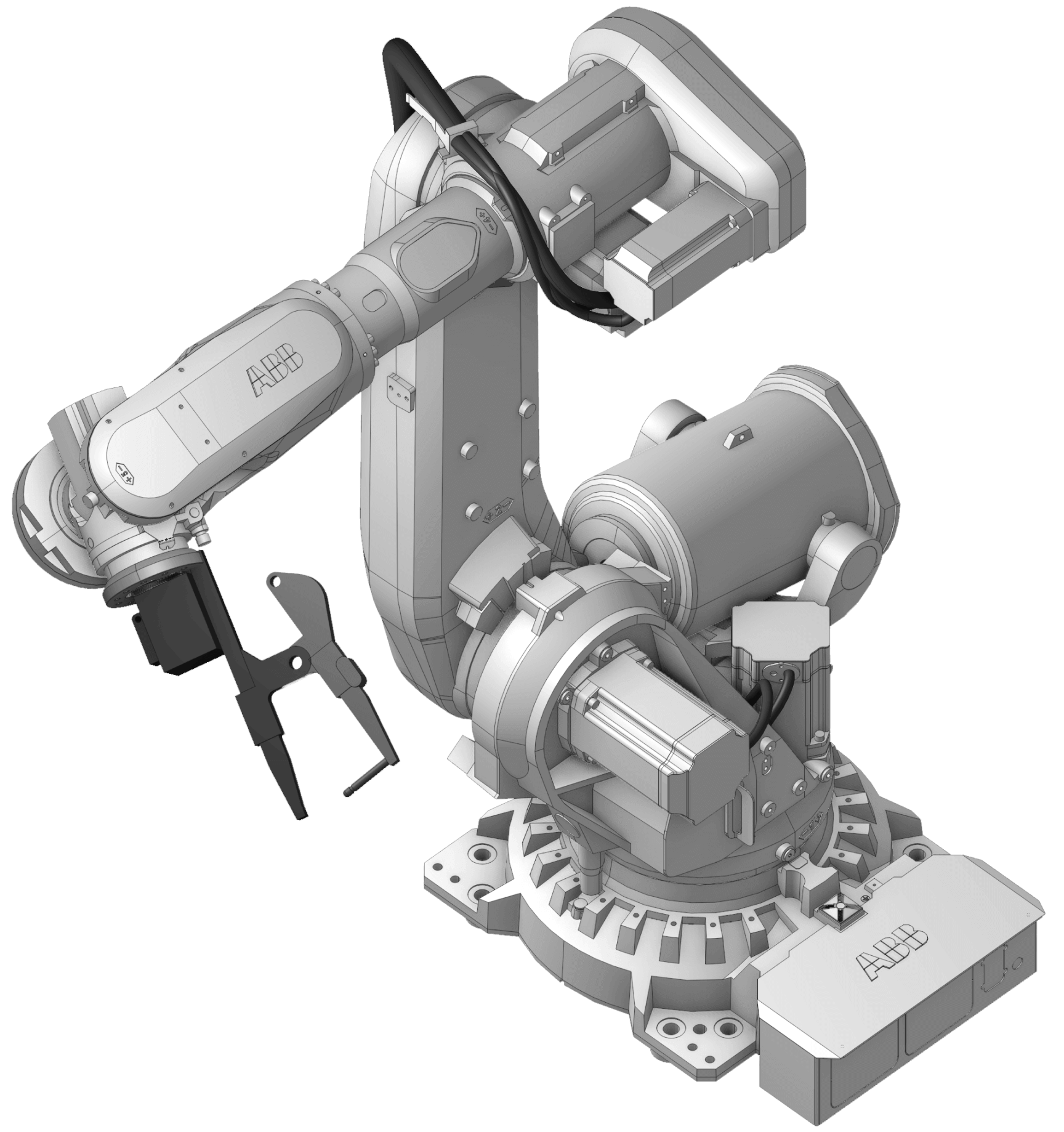

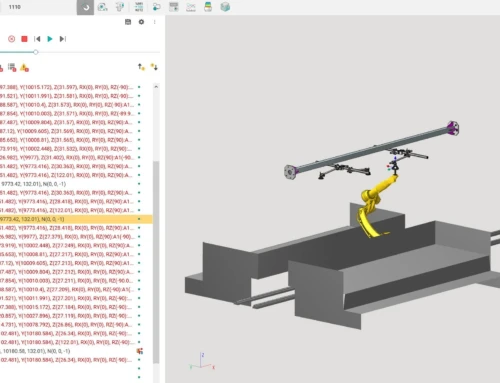

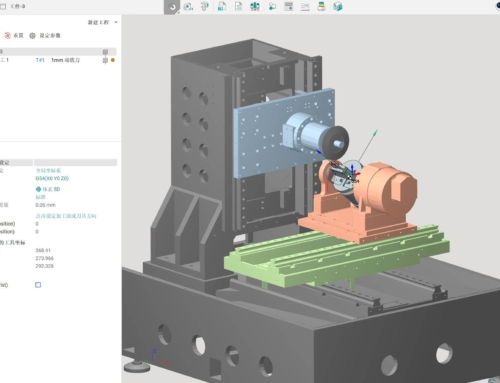

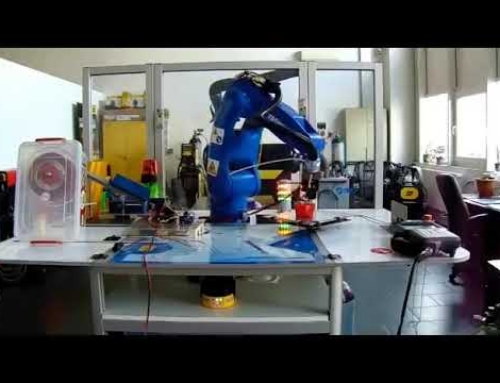

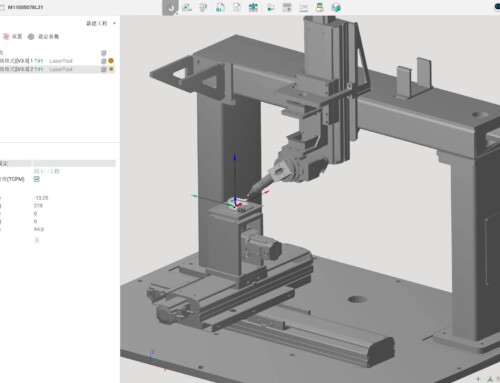

Our colleagues from China Sprut Software Technology (Kunshan) Co., Ltd. in cooperation with Heibei University of Technology have developed a groundbreaking 3D printing project that we will discuss today. They completed this grandiose undertaking in 2019, after dedicating an entire year to its creation. To bring it to life, they utilized a Kawasaki C180L robot and SprutCAM X Robot software.

Now, let’s talk about the construction aspect of this project. What do you use for your construction needs? It’s worth considering the possibilities of 3D printing technology, especially when combined with robotics. This allows for greater precision, speed, and efficiency, ultimately resulting in cost savings and increased productivity.

There are several advantages to using 3D printing with robots in the construction industry. For one, it allows for the creation of complex shapes and designs that would be challenging to achieve using traditional construction methods. Additionally, 3D printing eliminates the need for molds, which can be costly and time-consuming to produce. With robots, the printing process is automated, further increasing efficiency and reducing labor costs.

Of course, there are also some challenges to consider when using 3D printing and robotics in construction. For example, the materials used in 3D printing are often limited, and there are still some technical limitations to the size and scope of objects that can be printed.

However, with continued advancements in technology, we can expect to see more and more innovative uses of 3D printing and robotics in construction. It’s an exciting time for the industry, and we look forward to seeing what new developments the future holds.